The below text represents a souvenir handbook for the Bridgwater Industries Exhibition of 3 to 10 November 1948. It presents some interesting histories for some of the local businesses still operating in the town at that time, but also gives an excellent introduction to the industries of the town in the mid-twentieth century.

Foreword

MESSAGE FROM THE RT. HON. SIR STAFFORD CRIPPS,

K.C., M.P., CHANCELLOR OF THE EXCHEQUER.

EVERY part of the country has its own particular contribution to make to national recovery and it is desirable that local communities should be aware of the importance of that contribution and do everything possible to increase it.

Your Savings Production Week should do much to spread knowledge of the industrial products and achievements of your area and encourage a spirit of enthusiastic local support for all efforts to expand production.

To-day we are called upon, not only to produce more goods, but to produce them more efficiently, so that as the seller’s market declines we can maintain our competitive power in overseas markets.

This is of primary importance, since we are still not paying our way overseas and we cannot regain our economic security and independence until we are exporting enough to meet our bills for essential imports of food and raw materials for industry.

The need for savings remains as great as ever, for it is only by restricting our current consumption that we can set free resources for urgently needed new industrial plant and equipment.

I hope that success will attend your efforts.

BRIGHT AND BUSY BRIDGWATER

By R. F. WADDON

PROUDLY standing in the centre of “Smiling Somerset” and at the gateway to the glorious Quantock Hills, bright and busy Bridgwater, the home of a wide variety of industries, has many claims to importance.

A borough of great antiquity, a seaport, and an ideal touring centre within easy reach of some of the most beautiful scenery in Britain, it may well be described as a typical country town.

Enjoying a pleasing climate and consequent fine health record, Bridgwater, with its splendid array of shops, schools, striking buildings, many sporting attractions, amusements, historical connections and modern amenities, has much to offer both residents and visitors.

Approaching the town by the Bristol road, where a number of imposing factories have been built in recent years, one can appreciate why Bridgwater is developing industrially more rapidly than probably any other town in the West.

The main railway line, the main road from the North and Midlands, and the navigable river Parret all run parallel within a remarkably small compass.

Transport Facilities.

Thus, admirably served by three modes of transport, the town’s progress from an industrial angle, particularly marked in the last decade, is likely to continue. But, serving a large and prosperous agricultural area comprising over forty villages, it is retaining the importance it has enjoyed for many centuries as a thriving market town.

The modern cattle market is directly connected with the main line of British Railways (Western Region). On the Cornhill, the town’s historic and bustling centre, is a produce market. At the Docks may be seen vessels from far and near.

A feature of the river is the “bore”—a tidal wave.

In addition to the magnificent parish church there are places of worship for numerous denominations. The museum contains many relics of old Bridgwater, and of the battle of Sedgmoor, fought only three miles away.

Prominent among several open spaces are the picturesque Blake Gardens. There is a well-equipped public library, a charming Arts Centre, several clubs, dance halls, and three cinemas.

Devotees of almost every kind of sport and pastime are catered for. The Rugby and Soccer clubs’ attractive programmes draw four-figure attendances, and at no period of the year is Bridgwater without some sporting event.

Huge crowds invade the town for the old-established and popular St. Matthew’s Fair, and for the unique celebration, which coincides with this exhibition, of Guy Fawkes Night.

In the limited space available it is possible to touch only the fringe of Bridgwater’s amenities, attractions, buildings, trade, and commerce. There has been a town here since Saxon times. Its name is said to be a corruption of Bruge Walter, that is the bridge of Walter de Douai to whom William I gave the lordship of the town.

First Charter.

King John granted it its first charter, and a castle was built which remained intact until the 17th century. In the Civil War, Bridgwater was taken by Fairfax and Cromwell. The Duke of Monmouth was proclaimed King in the market place and from there set out on the night march which ended in his defeat at Sedgmoor.

On the Cornhill is a statue to the town’s greatest hero, Admiral Robert Blake.

Through the centuries Bridgwater has played its part in the history of our land, yet perhaps never more so than to-day, when the need for increased production in industry is so vitally important for our well-being.

Bridgwater & British Cellophane Ltd.

FOR 700 years or more the winding tidal reaches of the river Parret have carried traffic to and from Bridgwater port. Swiftly swelling, racing flood tides once brought in from the sea lanes the bluff, wooden vessels of Edward the Confessor’s time, even as in these days they assist the thrusting “tramps” to nose their way along the same approaches to the safe harbour in the centre of the town.

In the earlier days ships brought wode and wine and oranges from Spain, Italy and France and went down river again on a fast ebb tide with Somerset cloth, tiles and other goods for distant market destinations. Among English harbours Bridgwater ranked high. Nowadays, cargoes do not arrive so frequently, neither is the merchandise brought in so varied nor so stimulating to romantic minds as were those of earlier days.

Bridgwater is still a busy town however and during the past decade has acquired a much wide: degree of importance, a new greatness as a west of England centre of industrial activity and enterprise.

To that greatness “Cellophane” cellulose film, produced in Bridgwater by hundreds of skilled operatives, chemists and technicians, domiciled either in Bridgwater or the immediate environs, contributes a substantial and valuable part.

Manufactured primarily for the protection and better merchandising of the world’s pre-packed goods, this coveted brand of cellulose film is only produced in Bridgwater and solely by the owners of the trade-mark in the British Isles, British Cellophane Limited.

In the modern, familiar red-brick factory situated in the Bath Road, employees enjoy general working conditions as well as welfare, educational, and sports facilities second to none in the country.

The display unit in the Industrial Exhibition illustrates the importance of the Company’s contribution to the national export drive. During the post-war years British Cellophane Limited have become the largest exporters of transparent cellulose film in the world—a fact which speaks for itself and one of which Bridgwater can justifiably feel proud.

Quantock Preserving Co., Ltd.

QUANTOCK Preserving Company have manufactured preserves in Bridgwater during the past 26 years, and employ quite a large labour force, of both men and women. Since the beginning new buildings have been erected, and the old buildings re-built, so that today the factory can be classed as being thoroughly modern, both as regards buildings and machinery. During the past years some very elaborate machinery has been installed. Sugar, for instance, is subject to a process when being made into syrup, that even takes out specks that cannot be seen with the naked eye. Oranges are cut up by machines, that divide them into four, then takes out the inside, leaving the skins perfectly clean to be cut into shreds for marmalade. Each machine will deal with 25 cases per day.

Gooseberries go through a cleaning machine, which not only “tops and tails” them, but also takes of the hairs. Blackcurrants are also de-stalked by machines, that have fingers pulling the stalks off. Hundreds of tons of fresh strawberries are dealt with each year, but unlike most other fruits these have to be stalked by hand. Then there are four machines that take the stones out of fresh plums, and as much as 80 tons a day can be dealt with when working at full pressure. Another machine will cut up apples into small pieces at the rate of 20 tons a day.

The skins of apricots are taken off by machine, which also takes any leaves of the fruit. After the jam is made it is then conveyed to the filling machines, which fill the jam to the exact weight in the various sizes of tins and jars. All this is after being boiled in special pans, which are actually fed by syrup in stainless steel pipes, direct from automatic weighing machines, without being touched by hand. In the same way the fruit used in mincemeat and Christmas puddings is cleaned by special machinery. Large quantities of bottled fruits are turned out each year, and distributed all over the British Isles. Thousands of tons of peel, too, are processed for sale to the public, and cake manufacturers. Quantock Preserves and Mincemeat have been awarded the Gold Seal of the Royal Institute of Public Health and Hygiene, and this is the result of cleanliness and high quality.

The Somerset Trading Co., Ltd.

FOR over a hundred years this Company has played an active part in the commercial life of the town of Bridgwater, whilst its clay products have been distributed throughout the British Isles and indeed throughout the Empire.

The merchant side of the business was of importance when conditions allowed for the greater use of the port of Bridgwater, but this has to some extent diminished of later years.

Side by side with this, however, the clay manufacturing side of the business was expanding and owing to the present day make-up of the building trade these two sides are not parallel and it was decided to dispose of the merchant business while concentrating the whole of the Company’s resources and activities on the manufacture of roofing tiles and fittings, for which the Bridgwater clay is pre-eminently suited.

At the Hamp Yard, the principal products are ridges and some tiles; at the Dunwear Yard are made many well-known patterns of single-lap hand-made roofing tiles, together with two important machine made tiles and land drain pipes ; at Chilton Trinity is the factory turning out attractive and varied designs of machine-made inter-locking tiles, making use of the most up-to-date mass production methods adapted to the peculiar properties of the local clay.

All three plants are served by raw material from the extensive clay-beds owned by the Company in the district, the overburden being carried by bulldozer and scraper machines of sufficient capacity to allow of future land reclamation for agricultural purposes.

The varied demands of plants of this nature are met by the Company’s own engineering staff in well-equipped workshops.

An efficient sales organisation is available for sales in both the home and export markets.

Welfare facilities are not overlooked, and the management and workers are linked by works committees.

The Company’s roofing tiles are making a definite contribution to the present housing programme on both component and traditional houses, and rightly claim to combine the factors of economy, appearance and durability so essential to the reconstruction of today and tomorrow.

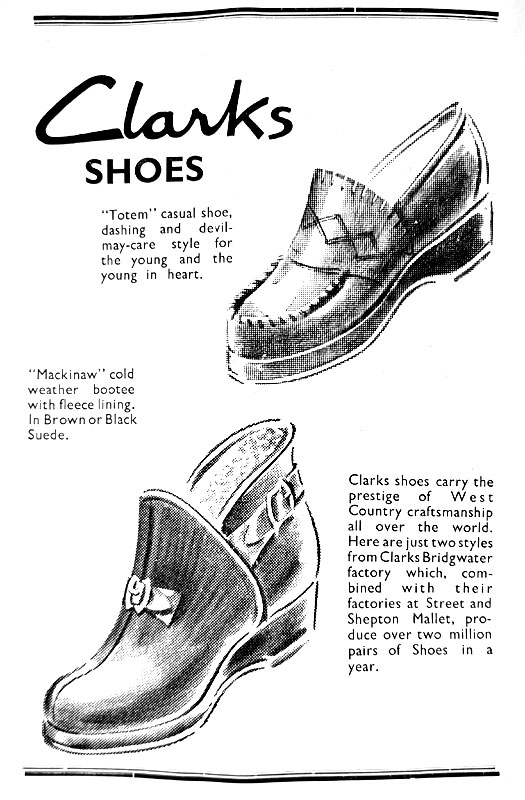

C. & J. Clark, Ltd.

CLARKS, the well-known shoemakers, have a large stand at the exhibition and their exhibits trace the history of the firm. The history of Clarks is in effect, the history of Street for the past 123 years, for it is around the shoemaking industry that a small agricultural village has developed into a town of some 5,000 inhabitants. First, Cyrus and James Clark with a small warehouse employed any skilled craftsmen available who worked in their homesteads. With the introduction of machinery, extension of premises was necessary and “out-workers” gradually changed over to “factory workers.” With more workers came the need for more houses and buildings in which to spend leisure hours. Two new roads, the Crispin Hall and a large library were included in these facilities. The firm has, despite all difficulties, doubled its pre-war output and now produces top-grade ladies fashion shoes and children’s shoes at the rate of two million pairs per annum, employing directly eighteen hundred people. A number of auxiliary services made Clarks almost self-contained. The wooden lasts are made in Clarks own modern wood turning factory whilst large, well-equipped engineering, electrical and motor transport departments handle any problems in their respective sphere. Clarks building staff and joinery department execute factory extensions and new buildings. The Bridgwater and Shepton Mallett factories are examples of their work. The future is viewed with confidence. £126,000 was invested in 1947 on fixed assets and the same is planned for 1948. In 1947 a new rubber factory was opened and three new factories for Street are mentioned in the “5 year” plan.

H. F. Tottle & Sons, Ltd.

THE firm of H. F. Tottle & Sons, Ltd., was founded by the present Mr. H. F. Tottle in 1908, who carried on business for some years in St. John Street. In 1925 new premises were built on the Bristol Road (the first factory to open up in this area) and these premises have been eventually added to, and were it not for the present restriction on building materials, would have been extended much more during the past two years. As a great number of people do not seem to know the meaning of joinery, we give a list of a few of the items manufactured at the Bristol Road Joinery Works : Staircases, gates, cupboard fronts, doors and door frames, linings, mouldings of all descriptions, windows, dressers, packing cases, church, bank, office and shop fittings, etc., all in any suitable type or class timber.

Kingsley (Art Furniture) Ltd.

IN the year 1918 after His Majesty the King had supported our firm we registered as our trade mark the name “KINGSLEY ” Registered. Later, in forming a company we used the name “KINGSLEY” for both our trade name and trade mark and so all goods with this name “KINGSLEY,” Registered, attached, is a guarantee of QUALITY and SERVICE.

We manufacture all we sell in our own self-contained factory which is situated near both railway stations. We have modern machines for cutting, sawing, rounding and bending and also spraying. The management and employees having grown up together, we claim personal supervision of all materials and orders, making our name “KINGSLEY” Registered the safeguard of quality and service.

The frame parts of all our chairs are bolted together (not nailed). Since the war the introduction of steel in our manufacture is taking a great part, whether for the best, time will tell, and as we claim to supply to customers’ requirements, we supply chairs with frames of hard cane or hard wood or hard wood and steel.

The frames of all our linen baskets, ottoman stools, etc., are half jointed and glued together to ensure strength, to give many years of use. Our upholstery is of the very best. The springs are of mild steel kept together with very strong web, and covered with special made to measure pads to ensure continual comfort.

We aim not to make chairs just to sit in but, to give that comfort which is the prime object of chairs.

All our goods are first sprayed with an undercoating material before the colours are sprayed on to ensure durability; customers can be supplied with goods in their natural state, in plain colour shades or colours shot with gold or silver.

Shopping baskets, waste paper baskets, dog and cat baskets’ cycle baskets, hampers, cradles, etc., are all made with best Somerset grown willows and in the hands of our craftsmen, our baskets are of the well made solid type to give years of continual uses.

With the best materials together with the best craftsmen we know our guarantee is safe. Incidentally, our staff comprises almost 100 per cent. ex-servicemen.

W. & F. Wills, Ltd.

THE firm of W. & F. Wills, Ltd., was founded in 1876 by Mr. Frank Wills and his cousin, Mr. Walter Wills, for the purpose of constructing steam engines. With the passing of the Motor Vehicles Act in 1896, Mr. Frank Wills purchased one of the first motor cars to ever run in Bridgwater, and from this very early beginning, his interest in motor vehicles developed, and later turned the attention of the firm to the manufacture of component parts, a business which they have carried on ever since.

Today W. & F. Wills are producing for the motor trade, camshafts, crankshafts, cylinders, crankcases, and other smaller components,

In addition, low and high pressure valves, low and high pressure unions, brick and tile making machinery, reversible flow pumps, printing machines, and hydraulic eroders, are among their activities.

The firm has a world-wide reputation for the excellence of its products, and the first class workmanship which had always been connected with the name of Wills.

It is interesting to record that although this firm has this year celebrated its 72nd birthday, the management of it has always been _ in the hands of the Wills family. Mr. Arnold Wills whose untimely death occurred in May last, succeeded Mr. Frank Wills as Managing Director.

The present Managing Director is Mr. Percy Wills and a brother Mr. Tom Wills holds the position of General Manager.

The Company is justly proud of the long record of service held by many of its employees, a number having a record of fifty or more years service.

The associated Company, Wills Pressure Filled Joint Ring, Ltd., was formed in 1932, to deal with the production of the Wills patent pressure filled joint ring, which is one of the best mediums known in the engineering world for obtaining a satisfactory joint to withstand high pressures. To quote a well-known user “You fit them and forget them.”

Distribution in Great Britain, Northern and Southern Ireland of this product is in the hands of Messrs. Delco-Remy & Hyatt, Ltd., a division of General Motors and abroad by General Motors Sales Organisation.

Coates’ Fencing, Ltd.

ALMOST everyone owns or rents a certain amount of land. It may be a small kitchen garden or a farm, or perhaps an estate. In either instance, the pride of ownership demands a proper and tangible boundary between one and the adjoining property. It may be that this boundary has also to be proof against man or beast. In some cases it has to keep a tennis ball in bounds and others to give privacy. In these and many ways a boundary fence in-creases the amenities of the land to which it belongs.

These varying conditions demand many different kinds of fences. The art of the fencing contractor is to determine the most suitable for his client’s needs. It is his duty to suggest means of eliminating unnecessary expense and yet consider the factors which might destroy his handiwork. It was for this somewhat unusual task that, within the framework of the family business (which had been established since 1819), Mr. W. 0. Coate started “Coate’s Fencing Service,” in 1929.

By 1931 the new venture had become firmly established and was then registered as a separate Limited Liability Company with the title of “Coate’s Fencing Limited.” The Firm operates over a wide area and its fences and gates are found in almost every town and village in the country. In recent years the – manufacturing side of the organisation has been considerably expanded. Steel gates are mass produced by modern machinery in a variety of attractive designs. The Company are the inventors of SUPERLAP Interwoven Fencing which is similarly produced at the Bridgwater factory. It is an interesting sidelight on the business to note that all the employees enjoy a share in the firm’s profits.

A. C. Gill & Co. (Bridgwater) Ltd.

THIS business was established in London 50 years ago. The London factory was completely destroyed by enemy action in 1940 and the Directors, on their return from active service, decided to move out of London, and after careful consideration the present factory was built in Bridgwater. The Company has always made high class furniture and although the material position is difficult at present every care is taken to ensure that the furniture produced—at the moment bedroom suites—is of high standard. For the present all furniture manufacturers are required to ma-facture Utility furniture only, but it is hoped that before long complete freedom of design will be restored. The Company are assisting in the export drive by manufacturing a number of radiograms for export only.

Crypton Equipment Limited

IN the early 1890’s two Companies—The Crypton Electrical Company, London, and Newtons of Taunton (Somerset)—commenced business as manufacturers of Electrical Machinery. Both firms carried on a successful business until at the beginning of the 1920’s their interests began to change and expand. The Crypto Electrical Company became associated with The Lancashire Dynamo and Motor Company Limited, of Trafford Park, Manchester. This connection eventually led to the formation of Lancashire Dynamo and Crypto Limited—now one of Britain’s best known, largest and most successful manufacturing electrical engineers. Newtons of Taunton became associated with Joseph Lucas, Ltd., and the result of this association was responsible for the development by Newtons of Taunton of a range of specialised equipment for the servicing of motor transport. 1 n 1935 the Lancashire Dynamo and Crypto and Newtons of Taunton interests were amalgamated; the former Company acquiring all interests in Newton garage equipment. This brought about the formation of Crypton Equipment, Limited, and the Crypton Company took over the manufacture c:f the full range of Newton garage equipment, also the specialised battery charging apparatus previously manufactured by the Crypto Company. Upon the formation of the Crypton Company it was decided that it should carry forward some identity of the original two firms. This decision resulted in the word “CRYPTON” which embodies the first four letters of “CRYPTO” and the last three letters of “NEWTON.” Since its formation in 1935, the Crypton Company has developed into the largest British manufacturer of specialised automobile engine i and electrical service equipment and its range of battery charging apparatus is more complete than that of any other manufacturer in the world. The Company’s products have earned a world-wide reputation for sound quality and high reliability.

Gallannaugh and Nicholls.

MESSRS. Gallannaugh and Nicholls, chartered architects, have been established in Bridgwater for the past 31- years and selected Bridgwater for their main office due to its central position and being convenient to operate from in giving service over the whole of the South West, including Bath in the northern area and Exeter in the Southern area. The firm’s Plymouth office deals with activities South of Exeter to Lands End.

Elliston, Evans & Jackson, Ltd.

THIS Company has been established 35 years and two of the original three directors still take an active part in the business. During this period it has developed and patented specialised apparatus (branded “ELEVANJA”) comprising electro-mechanical brakes, electro-magnets, automatic electric control gear and safety devices for lifts and industrial machinery, the apparatus being extensively used by H.M. Government Departments, the principal Railway Companies (now British Railways), Docks and Harbour Boards and large industrial undertakings. The products are principally used on electrically driven lifts, cranes, transporters, slipways, bridges, machine tools, rolling and rubber mills, etc. They are manufactured entirely by the Company including the castings which are produced in the foundry. Owing to the increasing demand, additional factory space was required, and in the latter part of 1938 the freehold land and buildings in Bridgwater were acquired. During the whole period of the last war both factories were fully employed manufacturing apparatus to the Company’s designs for Government contracts and it was fortunate in not having the London factory in either the 1914-18 or last war damaged except slightly by incendiary bombs and blast, although it is situated in Central London. At the present time, contracts are in hand sufficient to keep both factories fully employed well into 1950, these contracts embracing apparatus for most of the new generating stations, gas works, mechanisation of mines and modernisation and rehabilitation of docks and harbours in this country. In addition a large proportion is for export to South America, Canada, Australia, New Zealand, Egypt, Turkey and most of the European countries.

E. D. C. Ltd.

THE Electro Dynamic Construction Co., Ltd., of St. Mary Cray, Kent, established in 1940 at Bridgwater a branch factory to meet the Government’s demand for increased production of the Company’s specialised electrical products. With the cessation of hostilities it was found necessary to build additional premises to provide for the Company’s products in Bridgwater. The products displayed at the Exhibition give some indication of the activities of the Company, and also the subsidiary Companies in Bridgwater, enumerated as follows:_

ELECTRO DYNAMIC CONSTRUCTION CO., LTD. Fractional horse-power motors, rotary converters and generators.

SEALED MOTOR CONSTRUCTION CO. LTD. Deep-well pump units, and shallow well pumping equipment.

BATTERY CONSTRUCTION LIMITED. Lead acid accumulators, radio, automobile, traction, and specially designed accumulators for use with scientific equipment.

The Bridgwater Wire Rope Works Ltd.

FOUNDED shortly after the First World War, The Bridgwater Wire Rope Works, Ltd., was incorporated as a limited company in 1923. The original premises were in Momouth Street, but they were not ideal for rope-making and, some years ago, the Works were moved to their present site on the Bristol Road. As its name implies, the Company is mainly concerned with the business of making steel wire ropes. Manufacture of all types of these is carried out at the works and the uses to which they are put vary from the trawl warp, for the fishing fleets, to the small but essential scaffold lashing. It is not possible to give a complete list of the applications of the Company’s products—their applications in various industries are limitless—but, whatever the use for which a rope is required, a suitable rope is manufactured at these Works and can be supplied promptly. The history of an industrial concern such as this is of little interest to others than those in one way or another occupied in it. But we may say that, throughout the years in which it has been established, The Bridgwater Wire Rope Works, Ltd., has kept abreast of the times. The present policy of the Company is based on one principle—complete satisfaction of the customer—and to this end everything is devoted. Advice on the use of steel wire ropes can be obtained by writing, calling at or telephoning the works, and users and potential users are invited at any time to see their ropes in manufacture. In the past, the Company was even concerned in the domestic field by the manufacture of clothes lines. During the war, this contrast with the large ropes supplied for shipping, mining and engineering, had to stop on account of other urgent commitments, but it has now been recommenced, and we hope that soon Bridgwater clothes lines will make their mark—though not literally—all over the country. Every industry—from agriculture to steel-making, from shipping to flying—uses the wire rope; and Bridgwater is proud to possess a works which can meet any one of their requirements.

Brintons, Ltd.

MESSRS. Brintons are the oldest extant carpet firm in Kidderminster. In 1783 William Brinton commenced a worsted spinning business and in 1819 his son Henry added to it a carpet manufactory. The introduction of the tapestry power loom in the early 1850’s followed soon after by the Brussels power loom out of which the cut-pile Wilton was later developed, revolutionized the carpet trade. Messrs. Brintons, guided by Henry Brinton and his sons, Henry and John, was one of the earliest firms to adopt the new processes. Owing to the untimely decease of Henry, senr., and Henry, junr., John Brinton found himself in charge in 1857 at the age of 30. He remained in charge until his death in 1914 and was one of the chief builders of the firm. The advent of Royal Axminster carpet in 1878 seriously challenged Tapestry and Brussels, but later, Greenwood’s gripper device enabled. the Jacquard mechanism for selecting colours to be used whilst retaining the predominant Royal Axminster fixtures. The gripper loom was patented by Brintons and Gripper Axminster was developed into one of its most successful activities eventually leading to the building and opening of the Bridgwater factory in 1938 under the direction of the present joint managing directors, Mr. C. C. Brinton and Mr. J. F. C. Brinton.

Axminster production required woollen yarns and a woollen spinning plant was installed in 1900. This was rebuilt in 1936 and is now (1948) to be greatly enlarged with the most modern machinery. The wars of 1914-18 and 1939-45 found the firm adapting carpet workers to making many munitions of war. These ranged from 4.5 H.E. shells and petrol feed propellors for the famous Vickers-Vimy (the first aeroplane to cross the Atlantic), to jerricans, gun mountings and mine clearers, in addition to huge quantities of blankets and webbings.

It has once more returned to carpets being the first in the trade to regain pre-war production level and to achieve its export quota. New processes are being sought constantly and new weaves have been developed, some of which are displayed at this Exhibition. Most of these goods are, alas, for export only; but as soon as conditions permit the home market will again become familiar with the carpets bearing the motto of Messrs. Brintons, Ltd., “Lux est Salus”.

Morgan Brushes Ltd., of Combwich

FOUNDED 1890 by Mr. Frederick Charles Morgan, who started the business at the age of 18. He was the eldest son of a family of brushmakers, whose experience extended over 150 years. He started the business on a capital of £2 in a small room near Tower Bridge, London. His working hours, at the bench from 6 a.m. to 6 p.m., after which a barrow was hired to take the products of his day’s work to the various shops within a radius of six to seven miles, this involved walking distances of upwards of 8 to 10 miles in all weathers, often returning between 11 and 12 o’clock before his work was completed. Meanwhile his business continued to grow, and after making several moves, finally settled at No. 60, Jamaica Road, Bermondsey in March 1900. From that time until 1930 his efforts were concentrated on the manufacture of high class brushware for the household, and industrial consumer, but at this time Mr. Morgan entered into partial retirement, and the style of the firm was altered to F. C. Morgan & Co., under the direction of Mr. J. Richardson, the present Director and Manager, who, with the continued support and assistance of Mr. Morgan, maintained the good name and reputation held by the firm. When the war came along, the business was in a further stage of growth, and larger premises were being sought, but the scheme had to be shelved until the cessation of hostilities.

In 1940 (December) the premises were destroyed by enemy action, and alternative accommodation was found, and an additional works opened at Lee Green, London. The search for new and larger premises was again commenced in 1945, but success in this direction did not come until the end of 1947, and early in the present year the company took over the “Mill” at Combwich, for this purpose, when; it is hoped they will be able to transfer the bulk of their manufacturing from London within a short time.

Activities. During the war production for civil consumption was restricted, as the company were engaged on government contracts, but they are now engaged on manufacturing and supply of Brooms and Brushes for Industrial and the Export markets, and the latter represents approximately 33 1/3rd per cent. of their production, which consists of precision manufacture of high grade brushes for use as parts of machinery. This calls for a specialised knowledge, built up over many years of experience of the requirements of many and varied trades, and we claim that there are few trades who do not use brushes made by Morgan Brushes Ltd. It is our earnest hope that we may extend this claim to many new friends we hope to make in Bridgwater and the West of England.

Further Adverts