This sequence of pictures on the Technics of Coal-Gas Manufacture are from Vol 4 of Arthur Mee, Children’s Encyclopedia,10 vol. ed.,1922, and describe the sequence of work in a small gasworks. It has been featured here as background information to the history of Bridgwater Gas Light Co’s works at Old Taunton Road, which is being written.

The gas retorts are horizontal and needed to be filled with coal and emptied at regular intervals, a hot and dirty process as can be seen from the YouTube videos, attached. A vertical retort, where the process was continuous began operation at Bridgwater in 1912. An illustrated account of the this is at the end.

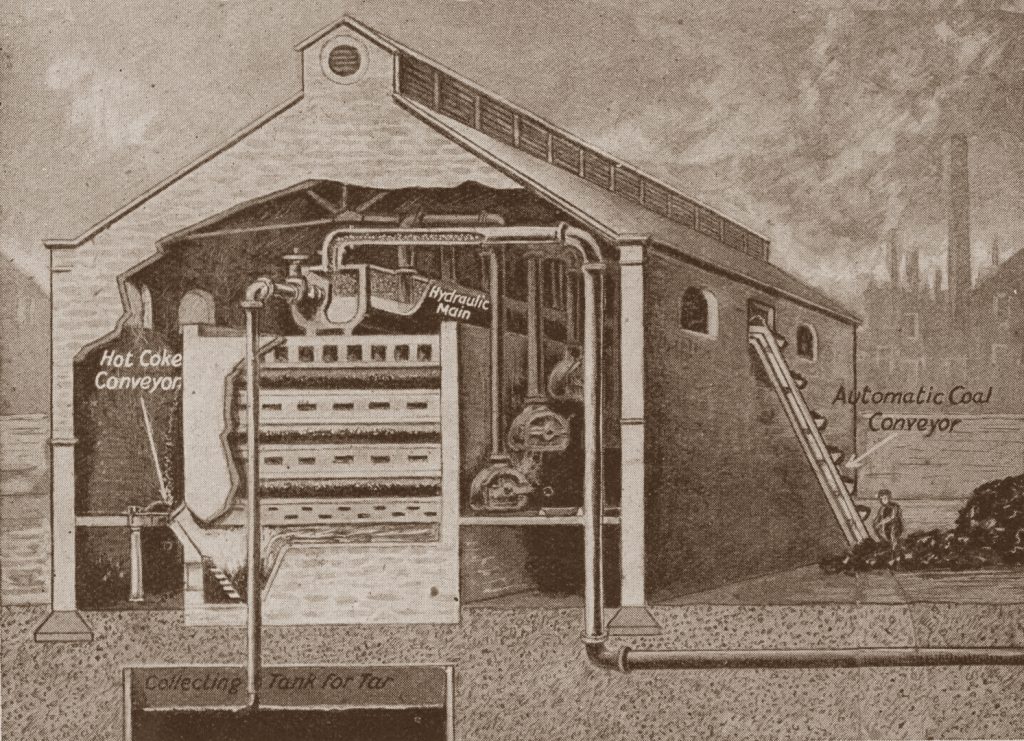

In this picture and those following we see the principle of gas-making as practised today. This simplified picture shows us the inside of the retort-house. When the coal arrives it is conveyed into the retort-house, as shown on the right. The retorts are stoked up, and the gas, mixed with various other vapours, is driven off through a hydraulic main, shown at the top. Some of the tar and oil with the gas condenses, and is collected in a tank, seen at the bottom.

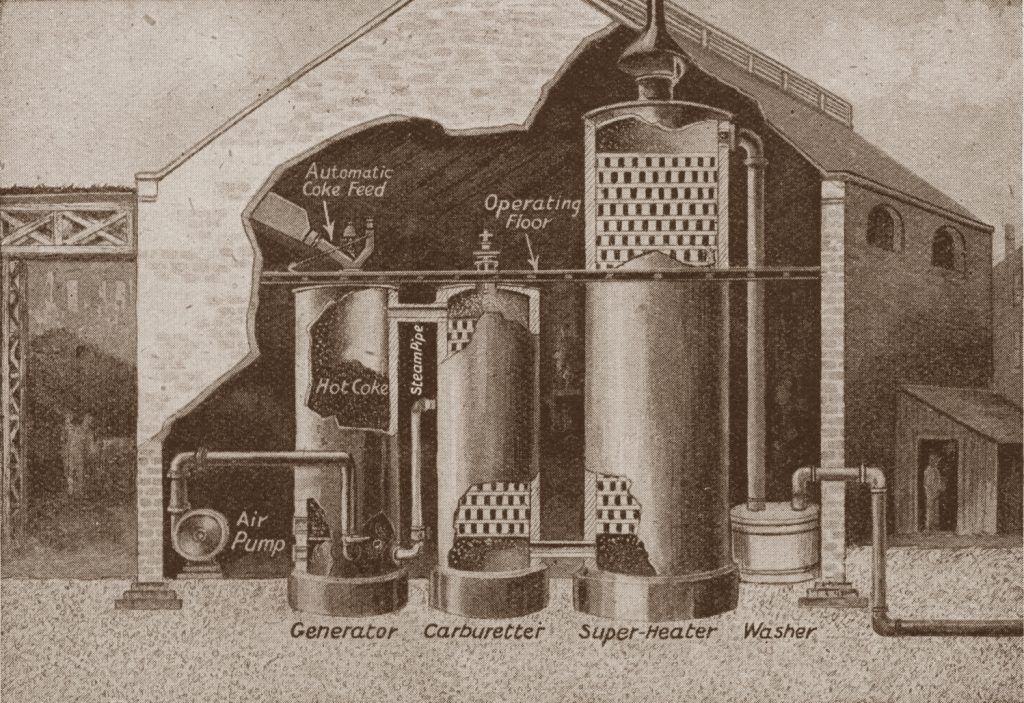

Here we see the, beginning of water-gas, which is produced by passing steam through red-hot coke in a generator The gas then .passes into, a carburetter, where oil is sprayed over a network of hot bricks and is changed into gas, enriching-the water-gas from the generator. This process is assisted by a super-heater.- Then the gas passes through a washer. When the steam cools the coke in the generator it is shut off, and air is pumped through from below to heat the coke up again;

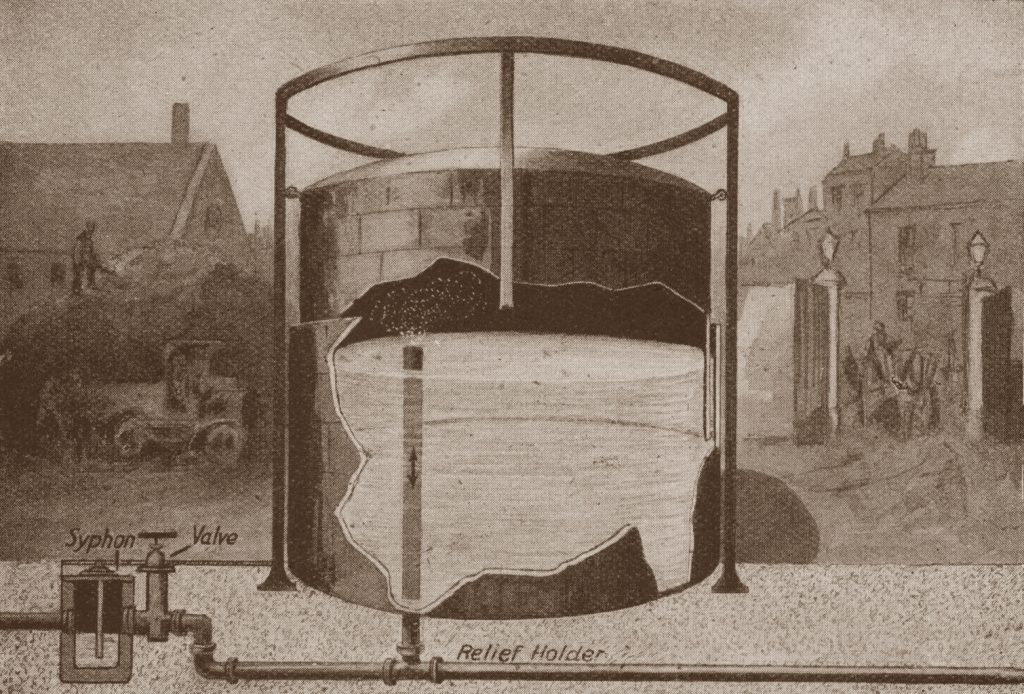

From the washer the water-gas goes to this vessel, called a relief holder, which is simply an ordinary gas holder, like an inverted cake tin, standing in water. As the volume of gas increases the holder rises, and when it decreases the holder descends. The purpose of passing the water gas into this relief holder is to insure that the delivery of gas to the exhausters which mix it with the coal-gas, may be regular

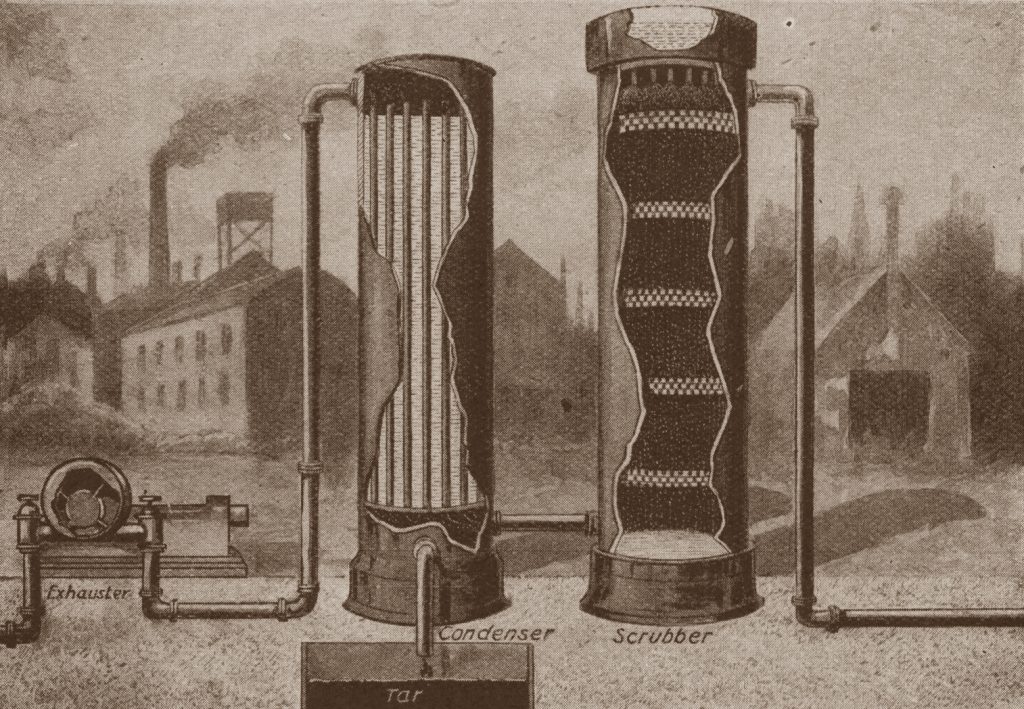

The coal-gas is drawn from the hydraulic main, seen in picture, by exhausters, which mix it with the water-gas and .then pass the combined-gases through tubes in the condenser, the big cylinder seen on the left. Water circulates round these tubes, cooling the gas and condensing the tar and oil into a liquid which flows out below. The gas passes from the tubes of the condenser into the scrubber, or -washer, where water playing on wooden trays washes the impurities down.

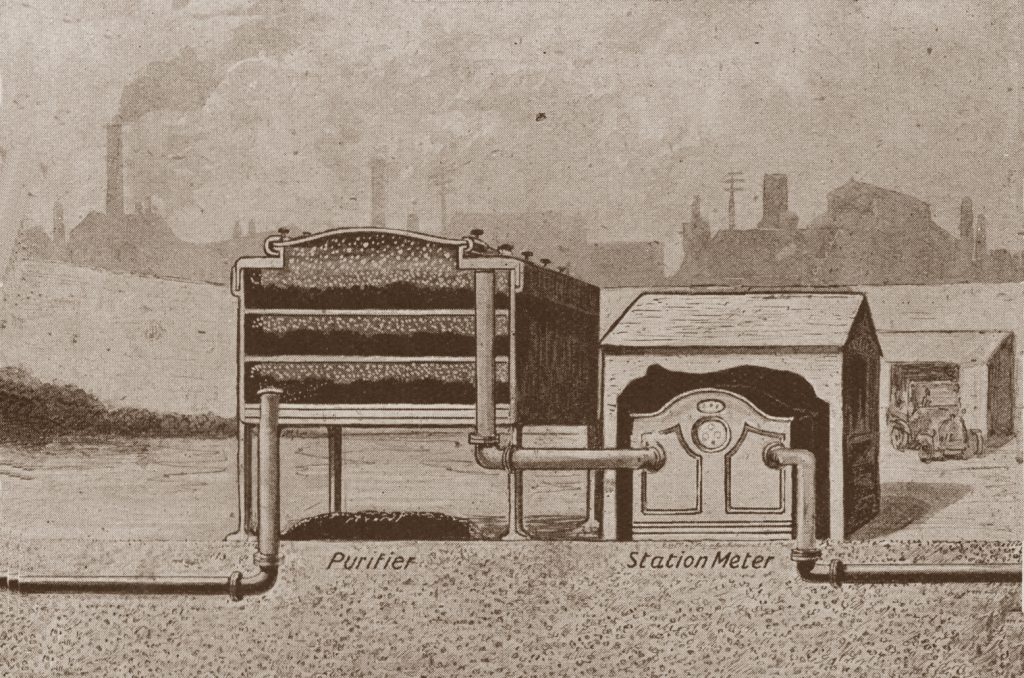

After various bye-products and impurities have been washed out in the scrubber, shown in the previous picture, the mixed gas goes to the purifier, where it is passed over trays of oxide of iron, and the sulphur impurities are absorbed by the iron. Under the purifier can be seen a pile of iron oxide drying. The gas now passes through the station mete, which measures its volume before it goes into the gas holder, seen in the picture below

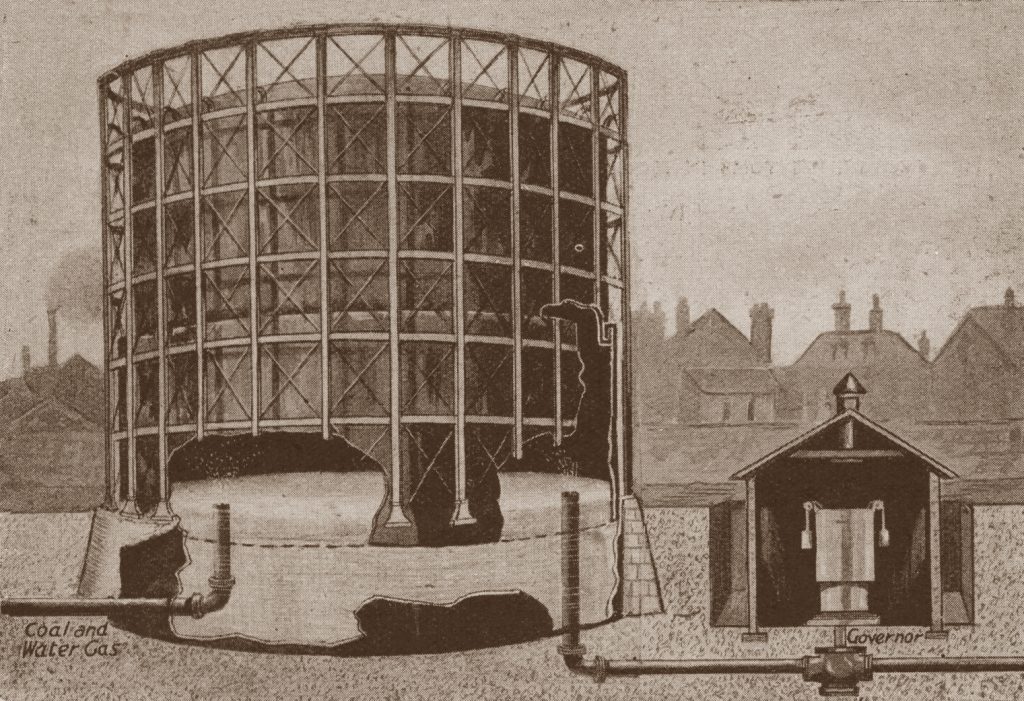

After passing through he station meter, seen in the previous picture , the gas goes to the gasholder, where it is stored ready for use. Like the relief holder for the water-gas, this is in the form of an inverted cake tin, but it is made in a of telescopic sections, and these rise or fall with the increase or decrease of gas from the purifier. The various sections have water-sealed connections to prevent the escape of gas. As the gas passes from the holder it goes through a governor that ensures uniform pressure, and so it comes to us for lighting and heating.

YouTube Videos

North Sea Gas and Gaswork Demolition

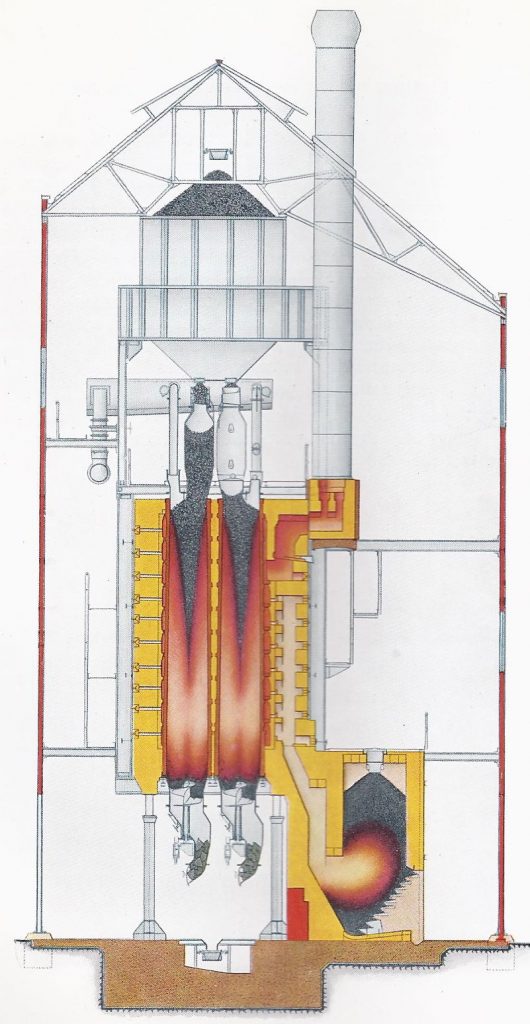

The vertical Retort

Illustration from a booklet about the Hoylake and West Kirby Gas Works,(Lancs) published in 1927. The Technics of Coal-Gas Manufacture.

In 1912 was started at Bridgwater a Glover-West Vertical retort, which operated by continuous carbonisation. The coal was fed into the top, dropped by gravity, and was removed from the bottom as cooled coke. The cloud of smoke and steam, resulting from the periodic charging and discharging of horizontal retorts, and the water-quenching of incandescent coke was entirely obviated.

Tony Woolrich 5 July 2020